in Digital Manufacturing

& Materials Characterization

WELCOME TO

Digital Manufacturing and Materials Characterization Laboratory

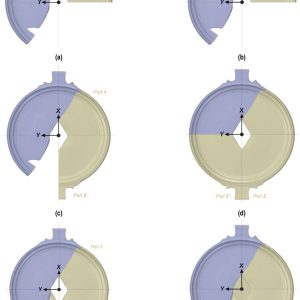

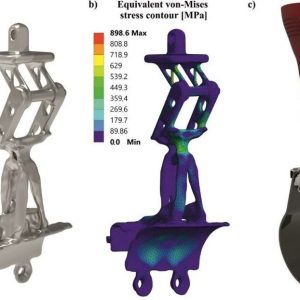

The DMMC Laboratory specializes in fundamental studies of materials, focusing on mechanical properties and behaviour under static and dynamic stress. The research spans biocompatible materials, thermoplastics, ceramics, and composites including lattice structure design. The laboratory conducts computational finite element analysis exploring manufacturing processes like 3D printing and custom material development.

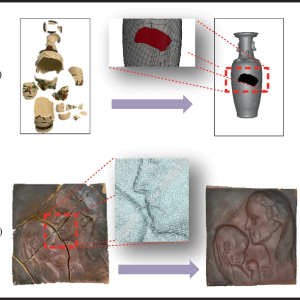

Equipped with state-of-the-art technologies such as 3D printing, 3D scanning, and SEM with EDX analysis, for the fabrication of high-precision products for research and real-life applications. The expertise of the laboratory and the personnel extends even further to 3D Computer Aided Design, Reverse Engineering Techniques, XR Applications and Machine Learning Approaches.

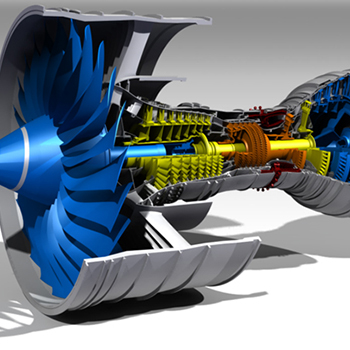

The Laboratory has also participated in several European and Greek funded research projects, in various areas including automotive and aerospace, biomedical engineering, archeology and culture, and pharmaceutics. The DMMC Lab is also used for external collaborations with industry partners, and other academic activities.

Service Fields

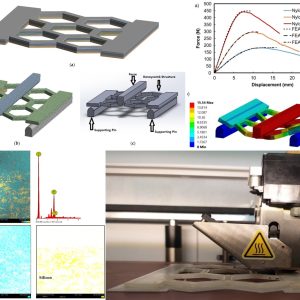

Engineering

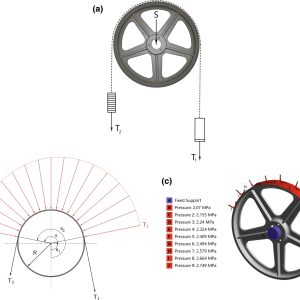

Topology Optimization and Finite Element Analysis for Engineering Applications

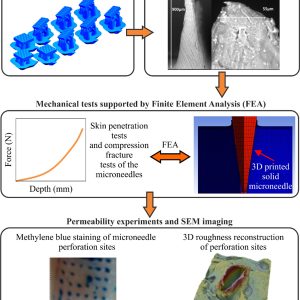

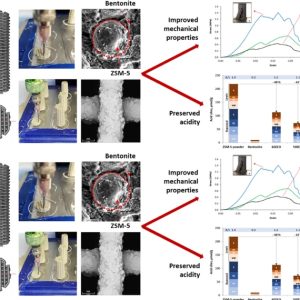

Pharmaceutics

3D Design and Micro 3D Printing for Pharmaceutical Applications

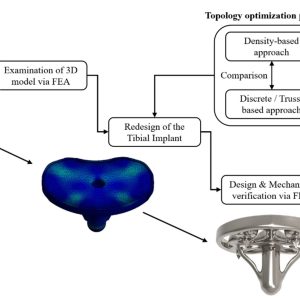

Biomedical

Materials Development & Characterization for Biomedical Applications

Culture

XR technologies for Virtual Museums and Exhibitions

Automotive

Reverse Engineering Methodologies for Automotive Design

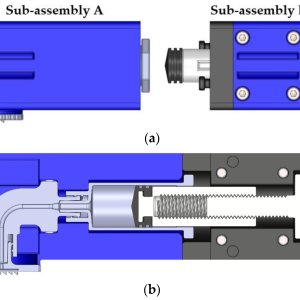

Industrial

3D Computer Aided Design Approaches for Industrial Design Projects

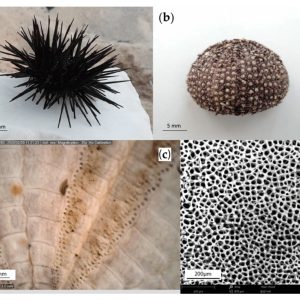

Biomimetics

Biomimicry Design Algorithms for Enhancing Mechanical Properties

Aerospace

3D printed Porous and Composite Materials for Aerospace Applications

Agriculture

3D Printed Biodegradable and Eco-friendly Materials for Sustainable Solutions

Architecture

Visual Programming Design Techniques for Architectural Applications

Facilities & Equipment

Fused Filament Fabrication (FFF) 3D Printers

Fused Filament Fabrication (FFF) 3D Printers- Independent Dual Extrusion (IDEX) FFF 3D Printers

- Pellet Extruder Head for Material Extrusion (MEX) 3D Printer

- Large Scale FFF 3D Printer – 1200x600x600mm

- Stereolithography (SLA) 3D printers

- Liquid Crystal Display (DLP) 3D Printers

- Continuous Fiber Fabrication (CFF) 3D Printer with CF and FG Reinforcement

- Selective Laser Sintering (SLS) 3D Printer

- Direct Ink Writing (DIW) / Robocasting 3D Printing System

Materials Testing Apparatus – Load Cells from 500N to 50KN.

Materials Testing Apparatus – Load Cells from 500N to 50KN.- Dynamic Ultra Micro Hardness Tester – Berkovich Indenter

- Dynamic Mechanical Analysis (DMA) – Temp. Range –170°C to 600°C.

- Desktop Laser 3D Scanner

- Handheld Whight Light Technology 3D Scanner

- Structured Light Technology 3D Scanner

- Unmanned Aerial Vehicle (Drone)

- 360o HD Camera

- Autonomous MR Headsets

- Scanning Electron Microscopy (SEM)

- EDX-Analysis,

- Fiber Metric Analysis,

- Particle & Poro Metric Analysis,

- 3D Roughness

- Digital Microscope

- Stereomicroscope

- Computer Numerical Control (CNC) Machine

- Laser Cutter/Engraver

- Electrospinning Device combined with 3D Printing.

- Kiln & Oven – Max. 1500 oC

- Thermal Camera – Temp. Range -40 to 650oC

- Polishing Machine

- Microtome

- Single & Dual Screw Extruder

- Sputter Coater

- Ball Milling

- Archimedes Apparatus

- Magnetic Stirrer

- Parametric Computer Aided Design (Solidworks)

- Computer Graphics & CAD (Rhinoceros3D)

- Visual Programming CAD (Grasshoper)

- Solid Modeling CAD (SpaceClaim)

- Finite Element Analysis (ANSYS-ANSA)

- Point Cloud Manipulation (Geomagic for Solidworks)

- Point Cloud Generator (Artec Studio)

- Computer Aided Manufacturing CAM (SolidworksCAM)

Empowering Innovation

- Parametric Product Design

- Cellular Solids Design (Lattices, TPMs, Honeycombs, Voronoi)

- Topology Optimization

- Biomimetic Design

- Design Programming

- Sustainability and Eco-design

- Static and Explicit Finite Element Analysis

- Computational Fluid Dynamics Analysis

- Representative Volume Elements

- Simulation and Validation of Experiments

- Simulations for Machine Learning

- Porous Materials for Biomedical Applications

- Ceramics for Gas Separation & Dental Applications

- Composite Materials for Automotive & Aerospace Applications

- Materials for Archeological Restoration

- Nanocomposite Materials

- 4D Printing Materials

- Conductive Materials for Microelectronics

- Flexible Materials for Soft Robotics

- Tensile and Compression Testing

- 3-Point Bending Testing

- Shear Puncture

- Cyclic and Step Measurements

- Nano-hardness Measurements

- Brinell Hardness

- Quasi-static Mechanical Properties Investigations

- Viscoelastic Properties Investigations

- Dynamic Mechanical Analyses from -170oC to 600oC

- Metrology in Engineering Applications and Analysis

- Digital Restoration of Archeological Findings

- Culture and Heritage Applications

- Virtual Museums and Exhibitions through MR Tools

- Micro CT Reverse Eng. Approaches for Biomedical Applications

- 3D Scanning Approaches for Digital Twins

- Photogrammetry Measurements for Outdoor Applications

- VR Tools for Serious Games

- Metrology in Engineering Applications and Analysis

- Digital Restoration of Archeological Findings

- Culture and Heritage Applications

- Virtual Museums and Exhibitions through MR Tools

- Micro CT Reverse Eng. Approaches for Biomedical Applications

- 3D Scanning Approaches for Digital Twins

- Photogrammetry Measurements for Outdoor Applications

- VR Tools for Serious Games